At MRG we work with a primary objective: that the natural gas circulating through our distribution network reaches our more than 890,000 customers 365 days a year without interruption and with optimal quality and safety conditions.

This is possible thanks to the staff that manage the 6,000 km of distribution network, with its auxiliary facilities, and that applies the highest standards of quality and safety included in our maintenance plan and in our risk prevention and personal safety policy.

In the current financial year, a total of 9.6 TWh was transported through our network, with a maximum contribution rate of 430,000 Nm3/h, with a normal behaviour of the network, which confirms the great capacity of the company to offer greater demands in the future, according to our network’s analysis models.

For another year, we have attended the emergency requirements for safety posts, with exceptional parameters in service times, which are below half an hour in highest priority service. All this has been possible because MRG has consolidated a multidisciplinary emergency management team, favouring the completion of complementary activities of various kinds 24 hours a day, 365 days a year, such as out-of-hours deliveries, Dispatching alarm management, attention to urgent claims, etc.

Once again, the maintenance plan for the networks and auxiliary natural gas installations has been successfully completed, with the usual quality and safety parameters, as well as the maintenance plan for the liquefied natural gas (LNG) plants, ensuring at all times the supply to customers related to these plants.

We have also complied with the objective of ensuring the completion of all network operation activities without any impact on the safety of people and goods, and for another year we have not had any serious accidents.

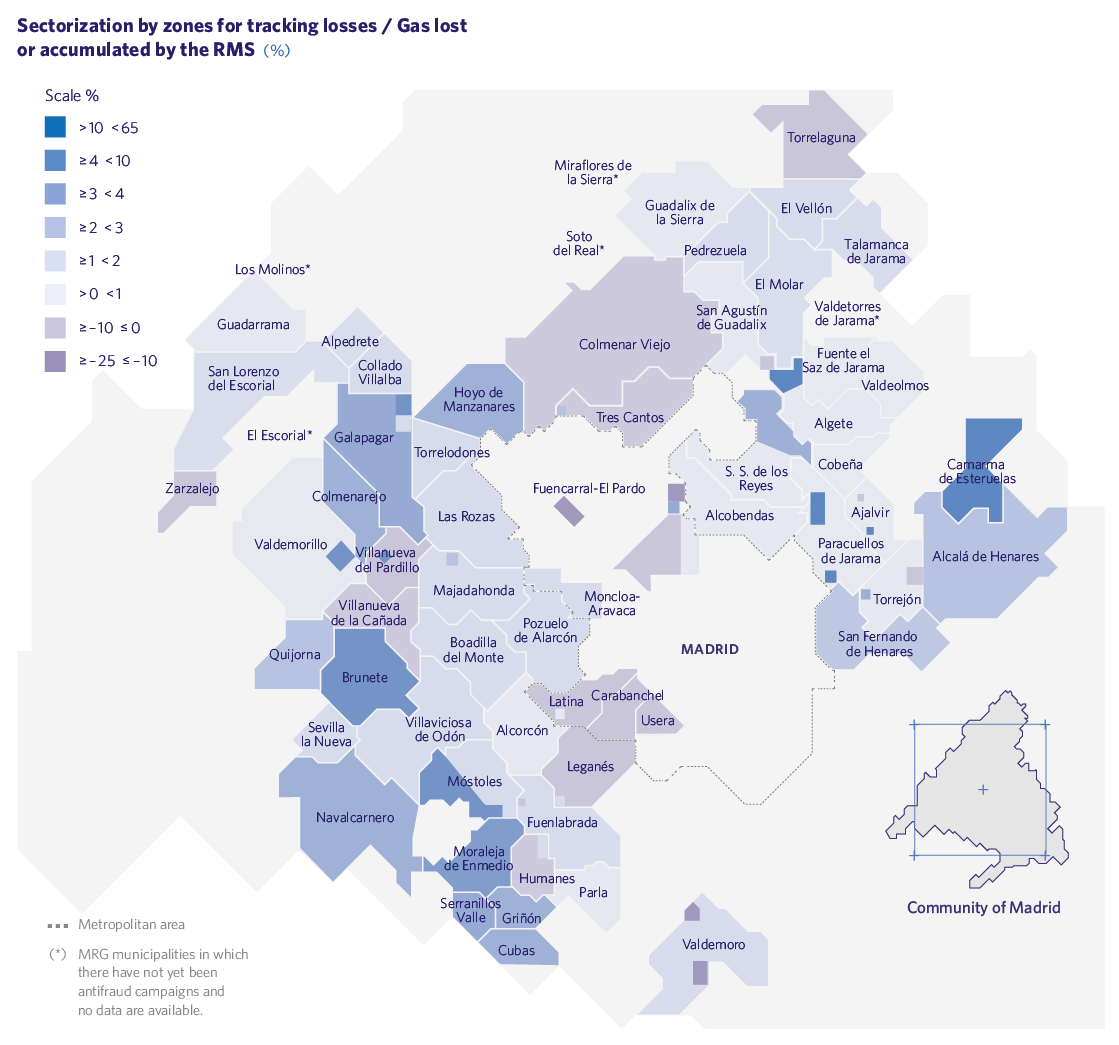

On the other hand, in this financial year, MRG has continued to carry out actions aimed at improving the information in the network. These actions have allowed us to increase the level of sectorization in areas associated with regulation and metering stations (RMSs) at the highest level that guarantee supply conditions allow. This information, collected in the information system of the distribution control centre, allows decision-making in waste reduction actions to be improved (see the graph on page 34).

In addition, we have carried out studies that allow more detailed sectorization of the emission areas and those that are still in the process of sectorization; among these are Leganés, Colmenar Viejo, Fuencarral and Alpedrete.

Similarly, we continued with the updating of the communications systems, replacing all PSTN communications with 3G modem, as well as the old Datalloger teleinformation systems with modern remote communication units. All of the alarm and operation signals of the LNG plants in the SCADA system have also been added.

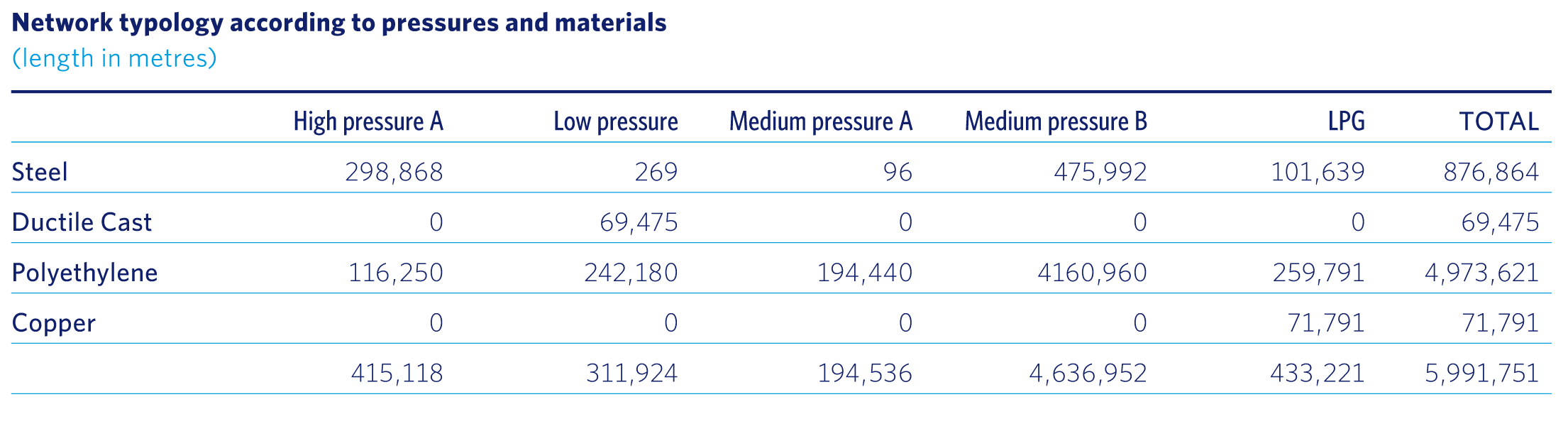

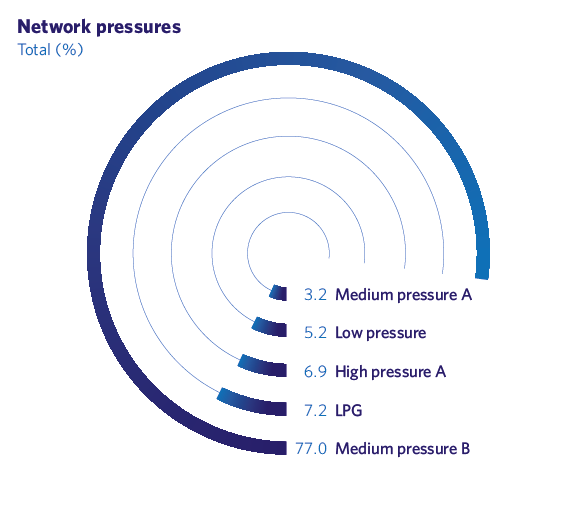

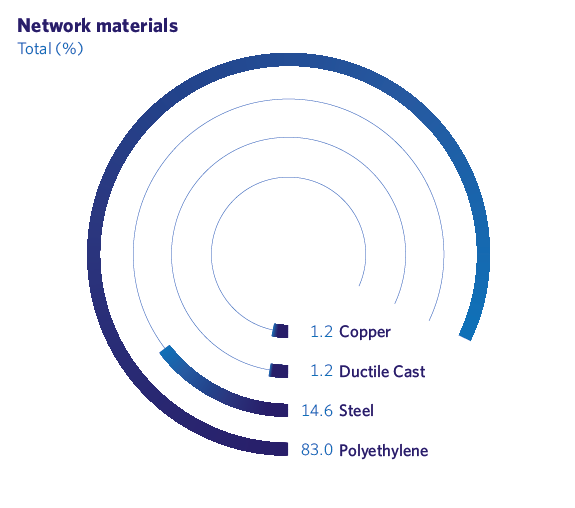

The MRG distribution network reaches 6,000 km and serves more than 890,000 customers. A total of 9.6 TWh of natural gas has been transported this year

The management of the new LPG project, which supplies 42,000 customers and has 390 km of associated networks, has been successfully incorporated into the operation of Madrileña Red de Gas

The management of the new LPG project, which supplies 42,000 customers, has been successfully incorporated into normal MRG operations. This operation has made it possible NETWORKfor the 516 LPG plants, with their 390 km of associated networks, to be satisfactorily included in our maintenance plans.

In concrete figures, during this year, 2,250 preventive and regulatory inspections have been carried out in these plants, 48 tank recalls, 381 gas tightness tests and 2,800 gas refills in tanks, which has successfully guaranteed the quality of the gas supply to our LPG customers.

In order to comply with the internal quality requirements of MRG on the constant supervision of LPG plants, which includes the project called “Improvement Plan for Safety Conditions in LPG plants”, we have installed 107 video surveillance cameras in 49 LPG plants. These devices have also been complemented with a programme of extraordinary visits to the facilities. In addition, we have incorporated all the information and documentation of the LPG project into our mapping system.

The information, collected in the information system of the distribution control centre, allows decision-making in waste reduction actions to be improved

The data reflected in this report correspond to the annual financial year, between July 1, 2016 and June 30, 2017.